Tour our Life Sciences Lab

Select an area on the map to tour a specific area of our lab or choose ‘Start Tour’ to start at the beginning

- Samples Receiving / Management

- Raw Materials

- Finished Products - SM

- Finished Products - LM

- Stability Testing & Storage

- Microbiology Sterile

- Microbiology Non-Sterile

- Facility Monitoring, Water Systems

- HPLC Instrument Lab

- Drug Release Dissolution

- Extractables Leachables

- Elemental Impurities

- Physical Functional Testing

- Contact Us

Samples Receiving / Samples Management

Thank you for trusting us to be your laboratory testing partner. We understand that preserving sample integrity is critical to your study and the success of your program and we take this responsibility seriously. Our dedicated professionals, working in specially-designed spaces for efficient receipt, processing and care for your samples take care of every detail:

- Immediately upon arrival, packages are inspected and samples with temperature-control requirements are stored appropriately

- Samples are entered into our Laboratory Informations Management System (LIMS) and bar-code labels are applied for tracking throughout sample life-cycle

- Samples are placed into dedicated storage locations (ambient, refrigerated, -20C, -80C, and others)

- Project Managers (PM) are notified for assignment of test codes and scheduling

- Clients receive a LIMS-System-generated Sample Acknowledgement Form (SAF) - this offers a tremendous opportunity to review and confirm that everything is on track, right from the beginning!

- Technical managers are notified for review and release of samples to the laboratory – your study can begin!

Throughout the whole of the testing cycle, samples are properly tracked, documented, stored, handled, and dispositioned. Proper regard to the importance of handling sample materials is an important piece of ensuring the integrity of the testing data we provide.

Raw Materials

Our raw materials testing team completes more than 30,000 monograph tests each year and maintains an impressive on-time-delivery record. We offer expedited turn-around time services for those times when results are needed quickly so you can count on meeting your “just-in-time” manufacturing processes.

Trusting us with your raw materials testing program offers you many advantages, of which these are just a few:

- Extensive experience testing API and excipients to the USP/NF, EP, JP, FCC and ACS monograph requirements

- Efficient installation and verification of client-supplied and vendor supplied methods

- Instrumentation to perform nearly all monograph and general chapter requirements

- Residual Solvents expertise with three (3) headspace sampling technologies

- Elemental Impurities using ICP-MS and AA Spectroscopy

- A robust Compendial Verification (CV) program to ensure validity of test results

- Our “compendial specialists” track updates, changes, and harmonization to the USP, EP, and JP

- Full data packages are available for review and auditing via PacePort, our web-portal

Our raw material testing supports R&D formulation development and finished product manufacturing programs from around the globe. Our years of experience and commitment to the highest level of quality and attention to detail ensures your raw material testing will be successfully executed and results will be delivered on time.

Finished Products - SM

Our finished products testing team is committed to the highest level of quality to support your specific testing needs. We have experience in a wide range of dosage forms, oral solid tablets/capsules, transdermals & topicals, sterile injectables, inhalation products, resorbable polymer depots, and other drug-device combination products.

Complex products require custom methods for accurate characterization of assay and impurities. Our team has a robust system of installation, performance verification of client-supplied methods and can provide complete methods development services with submission-ready validation protocols and study reports. Clients trust our team for our technical problem-solving, strong quality and regulatory compliance.

The experience, capability and capacity testing program is available to you:

- 50 + HPLC / UPLC Systems with UV-PDA, RI, FL, and Mass Spectrometer detector

- 50+ Drug Release / Dissolution Apparatus (USP App 1, 2, 3, 5, 6, and 7)

- Headspace and direct-inject Gas Chromatography

- NGI / ACI for inhalation drug delivery

- Physical testing of finished products, packaging and container-closure integrity

- Full data packages are available for review and auditing via PacePort, our web-portal

Our finished products program supports R&D formulation development and finished product manufacturing programs from around the globe. Whether you need timely finished-product release testing programs or support for long-term stability programs, our team maintains an impressive on-time-delivery record and can offer expedited turn-around time services.

Finished Products - LM

Here we provide full support for the development of new therapies and ensure the quality of marketed therapeutic proteins, synthetic peptides, enzymes, oligonucleotides, antibody-drug conjugates and specialty molecules. Our experts and extensive selection of testing equipment offer support to biopharmaceutical development, commercialization, stability, and release of marketed products.

Complex products require custom methods for accurate characterization of assay and impurities. We have a robust system of installation and performance verification of client-supplied methods and can provide complete methods development services with submission-ready validation protocols and study reports. Clients trust our technical problem-solving and our strong quality and regulatory compliance.

Our services to support the biopharmaceutical manufacturing industry:

- Binding & Potency ELISA assays

- Enzymatic Activity assay

- Capillary Charge Variant Analysis (CE-SDS, cIEF)

- Size Separations (Gel and Capillary techniques)

- Chromatography (Size Exclusion, Ion Exchange, Reverse Phase)

- Concentration Determination (UV-Vis Variable Pathlength)

- Impurities / Degradation Products

- R&D Method Development, Method Qualification, and Method Validation

- Physical testing of finished products, packaging and container-closure integrity

- Full data packages are available for review and auditing via PacePort, our web-portal

Whether you need R&D development, timely finished-product release testing programs or support for long-term stability programs, our team maintains an impressive on-time-delivery record and can offer expedited turn-around time services for those times when results are needed quickly.

Stability Testing & Storage

Our dedicated stability team is ready to support your ICH-compliant stability programs. We have the experience, resources, facilities, chambers, and tools to monitor, track, and maintain your R&D, registration and commercial stability programs.

We maintain more than 25,000 ft3 of stability storage space in many configurations and offer:

- Protocol drafting services and maintenance of client protocols

- Dedicated space for receipt, quarantine, labelling, reconciliation, and set-down of samples

- Effective inventory management of all samples by study and tracking within chambers

- Storage within qualified chambers with temperature and humidity continuously monitored and mapped at multiple points using our validated Continuous-Monitoring-System (CMS)

- Facility infrastructure to support our expanding programs, including on-site staff, back-up power generators, emergency-repair contractors on retainer, and out-of-tolerance alarms systems with notification that requires positive actions to resolve

- Maintenance of pull-schedules using validated LIMS-system modules with back-up systems in place

- Smooth transition of samples to laboratory for scheduled testing and reporting tailored to fit your needs

We maintain the highest level of attention to detail to mitigate risks and ensure that your stability program will be successfully executed and that results will be delivered on time. Custom storage conditions are available and new storage conditions are often added, so contact your project manager or account executive to discuss your needs.

Microbiology Sterile

At this next stop we assure you of well-designed sterility testing procedures, adherence to test methods, a fully trained cGMP staff, a qualified lab environment along with a well-supported quality assurance program. We understand that sterility assurance testing is a very demanding procedure that requires properly trained and qualified personnel. The full range of possible sample types from lyophilized powders, injectable solutions to ointments and creams to solids to aerosol products are supported by our talented teams.

Our services to support the all aspects of manufacturing industry:

- Procedures meet the requirements of USP, EP and ISO/AAMI standards for sterility,

- Microbial Bioburden, (ISO 11737-1)

- Sterility Testing (USP <71>) and Test of Sterility (ISO 11737-1)

- Bacterial endotoxins (USP <85>)

- Sub-visible particulates (USP <78>>)

- Biological Indicator testing

- R&D Method Development, Method Qualification, and Method Validation

- Physical testing of finished products, packaging and container-closure integrity

- Full data packages are available for review and auditing via PacePort, our web-portal

Sterility testing, at PLS, is carried out in aseptic conditions in a class 10,000 (ISO Class 7) clean room. Our lab personnel take all the necessary precautions from sample receipt thru the sterility testing process to avoid any contamination that could influence the outcome of a test. Our team of experts offers the services and expertise to support development, commercialization, stability, and release of marketed products. Clients continually trust our technical problem-solving and our strong quality and regulatory compliance.

Microbiology Non-Sterile

We always provide adherence to test methods, a fully trained cGMP staff, a qualified lab environment along with a well-supported quality assurance program. All testing is performed in compliance with current UPS/NF, EP, JP and client-supplied methodology. Custom protocols can be created to support product development, investigations, and unique testing needs.

Our services to support the all aspects of manufacturing industry:

- Procedures meet the requirements of USP, EP, JP and ISO standards

- Microbial Limit Tests (MLT), harmonized

- Antimicrobial Effectiveness Test (AET)

- Microbial Identification

- Purified Water and process water testing

- Clean Room/Controlled Environment/Facility Monitoring

- Disinfectant Efficacy Testing / Cleaning Verification Studies

- R&D Method Development, Method Qualification, and Method Validation

- Physical testing of finished products, packaging and container-closure integrity

- Full data packages are available for review and auditing via PacePort, our web-portal

Our team of experts offers the services and expertise to support development, commercialization, stability, and release of marketed products. Clients continually trust our technical problem-solving and our strong quality and regulatory compliance.

Facility Monitoring, Water Systems

We also offer field sampling services to help commission new facilities and to demonstrate control of manufacturing environments through routine periodic assessment. We ensure adherence to test methods, a fully trained cGMP staff, and a well-supported quality assurance program.

We can provide sampling services at your site, or we can perform the laboratory testing of the samples your team is collecting. Our services include:

- Facility monitoring / Water system monitoring

- On-site sampling services

- Sample courier services

- active air sampling for total particulates using a laser particle counter,

- active air sampling for viable particulates using RCS High Flow,

- surface viable sampling using contact plates (such as RODAC plates or HYCON Contact Slides), and

- Water sampling and testing to USP Purified Water:

- Total Organic Carbon (TOC)

- Conductivity

- Microbial attributes, such as counts and screening for specific organisms

- Disinfectant Efficacy Testing / Cleaning Verification Studies

- R&D Method Development, Method Qualification, and Method Validation

- Physical testing of finished products, packaging and container-closure integrity

- Full data packages are available for review and auditing via PacePort, our web-portal

Our team of experts offers the services and expertise to support your commercial manufacturing programs.

HPLC Instrument Lab

Liquid Chromatography techniques continue to be primary and central to characterizing the identity, purity (assay), uniformity, and control of process impurities and degradants of drug products. Our 3,000 ft2 chromatography instruments laboratory space offers you many advantages:

- Infrastructure to support our growing programs

- Back-up power systems

- Un-interruptible battery back-up power systems (UPS)

- Efficient installation and verification of client-supplied and vendor supplied methods

- Methods development services with submission-ready validation protocols and study reports

- Extensive HPLC / UPLC Instrumentation (50+ systems) to support a range of techniques

- Reversed-phase (RP-HPLC, RP-UPLC)

- Ion exchange

- Size-Exclusion, Gel-Permeation (SEC / GPC)

- Chiral

- Normal Phase

- Detectors to support a wide range of requirements

- UV-Vis Photo-diode array (PDA)

- Mass Spectrometer (MS/MS)

- Time-of-Flight Mass Spectrometer (MS-TOF)

- Refractive Index (RI)

- Evaporative Light Scattering (ELSD)

- Fluorescence (Fl)

- Conductivity

- Data Integrity

- Waters Empower 3 for instrument control and data acquisition, calculation, and reporting

- Peerkin-Elmer Electronic Laboratory Notebook (ELN) for worksheets, reference standard inventory, reagent tracking, and more

- Electronic Document Management System (EDMS)

- Full data packages are available for review and auditing via PacePort, our web-portal

Our facilities support R&D formulation development through finished product manufacturing programs from around the globe. Our years of experience, commitment to the highest level of quality and attention to detail ensures your testing will be done right and results will be delivered on time.

Drug Release Dissolution

Characterizing and monitoring the quality of drug products goes beyond identity and purity. The ability of the dosage form to deliver the therapy to the target site and then effectively release the drug immediately or over time are critical performance and quality attributes. Our Drug Release / Dissolution / Elution testing laboratory space offers you many advantages:

-

Extensive Dissolution / Elution Instrumentation (70+ systems) to support a range of techniques

- United States Pharmacopoeia (USP) Apparatus 1, 2, 3, 5, 6, and 7

- Custom client-designed apparatus

- Incubated shakers for drug-device combination products

-

Infrastructure to support our growing programs

- Back-up power systems

- Un-interruptible battery back-up power systems (UPS)

- Installed Yellow-light fixtures for working with light-sensitive compounds

-

Data Integrity

- Waters Empower 3 for HPLC/UPLC instrument control and data acquisition, calculation, and reporting

- Perkin-Elmer Electronic Laboratory Notebook (ELN) for worksheets, reference standard inventory, reagent tracking, and more

- Electronic Document Management System (EDMS)

- Efficient installation and verification of client-supplied and vendor supplied methods

- Methods development services with submission-ready validation protocols and study reports

- Full data packages are available for review and auditing via PacePort, our web-portal

Our facilities support R&D formulation development through finished product manufacturing programs from around the globe. Our years of experience and commitment to the highest level of quality and attention to detail ensures your testing is in the hands of industry experts.

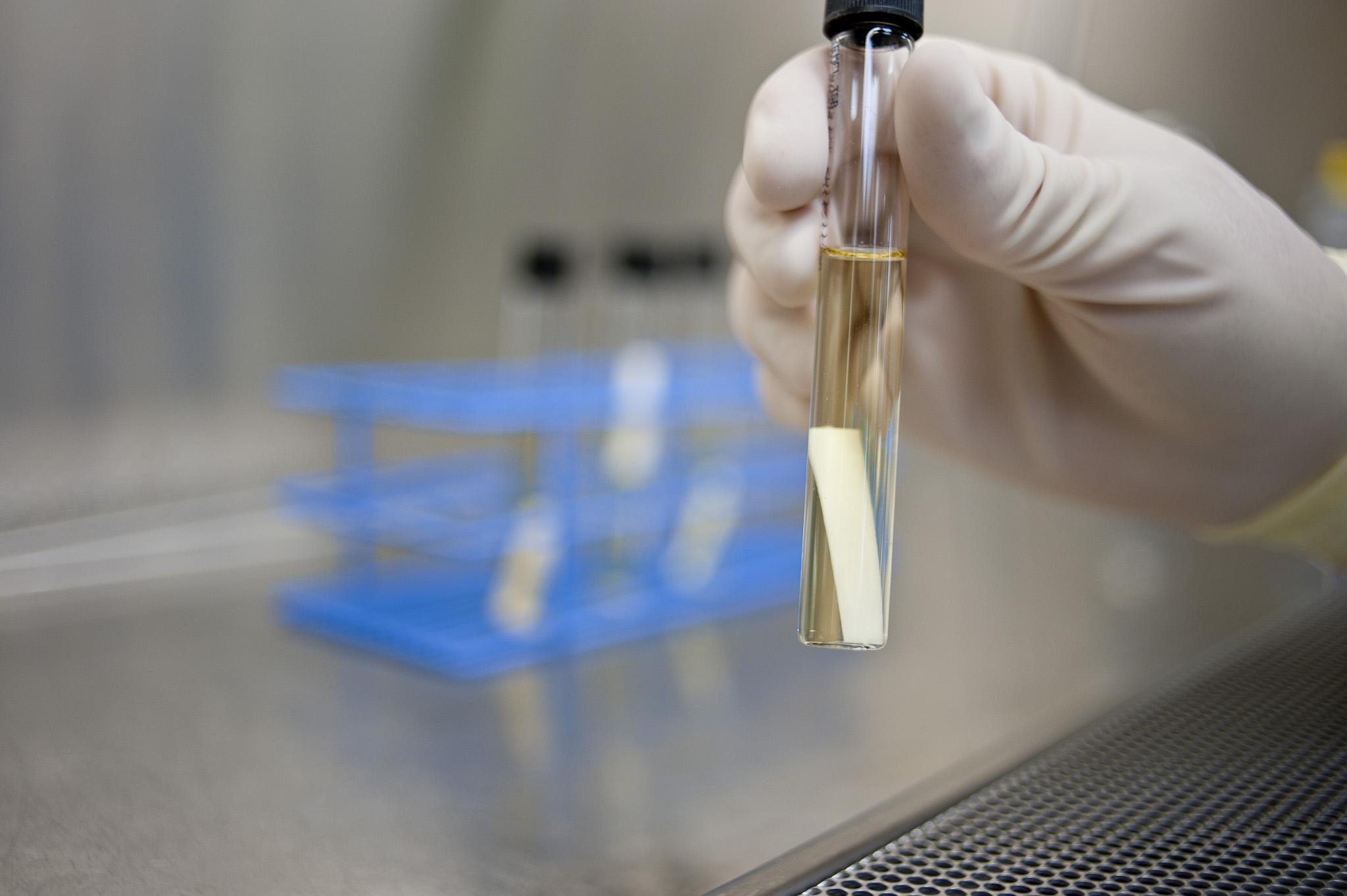

Extractables Leachables

Thorough characterization to ensure the safety, purity and effectiveness of pharma/biopharms drug products goes beyond testing of the materials and products themselves. A thorough evaluation of the container/closure system that comes into contact with a drug product is also needed and is the focus of our Extractables-Leachables team. The studies they perform will include extractions and chemical characterization intended to align with the guidance provided by the United States Pharmacopoeia General Chapters <1663>, <1664>, <1665>, and ISO 10993-18, Chemical Characterization of Materials, as appropriate for the products.

PLS teams perform controlled extraction studies for the purpose of characterizing a wide range packaging components and devices used in drug-delivery systems. Studies employ the use of multiple solvent systems of varying polarities: careful selection of study solvents provides extraction media that bracket and exceed the extraction potential required for the product and appropriately characterize the materials based upon the risk assessment profile.

The extracts may then be characterized for volatile/semi-volatile, non-volatile organic and inorganic compounds. Selection of analytical technologies should provide adequate data for tentative identification and semi-quantification of extractable compounds above the specified threshold. Various technologies, as specified in the protocol, will be used which may include:

- gravimetric non-volatile residue (NVR) determination,

- Direct Injection Gas Chromatography Mass Spectroscopy (DI-GC-MS),

- Static Headspace Gas Chromatography Mass Spectroscopy (SHS-GC-MS),

- Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), and

- Liquid Chromatography Mass Spectroscopy Time-of-Flight (LC-MS-TOF)

If compounds are identified in the controlled extraction study that would classify as potential leachables, based on toxicity assessments, limit-test or quantification methods specific to those compounds will be developed and validated under a formal protocol. Once the limit-test methods are developed and validated, an effective Leachables study can be performed either in simulated use or in coordination with a stability study.

PLS advantages include robust Data Integrity

- Waters Empower 3 for HPLC/UPLC instrument control and data acquisition, calculation, and reporting

- Perkin-Elmer Electronic Laboratory Notebook (ELN) for worksheets, reference standard inventory, reagent tracking, and more

- Electronic Document Management System (EDMS)

- Full data packages are available for review and auditing via PacePort, our web-portal

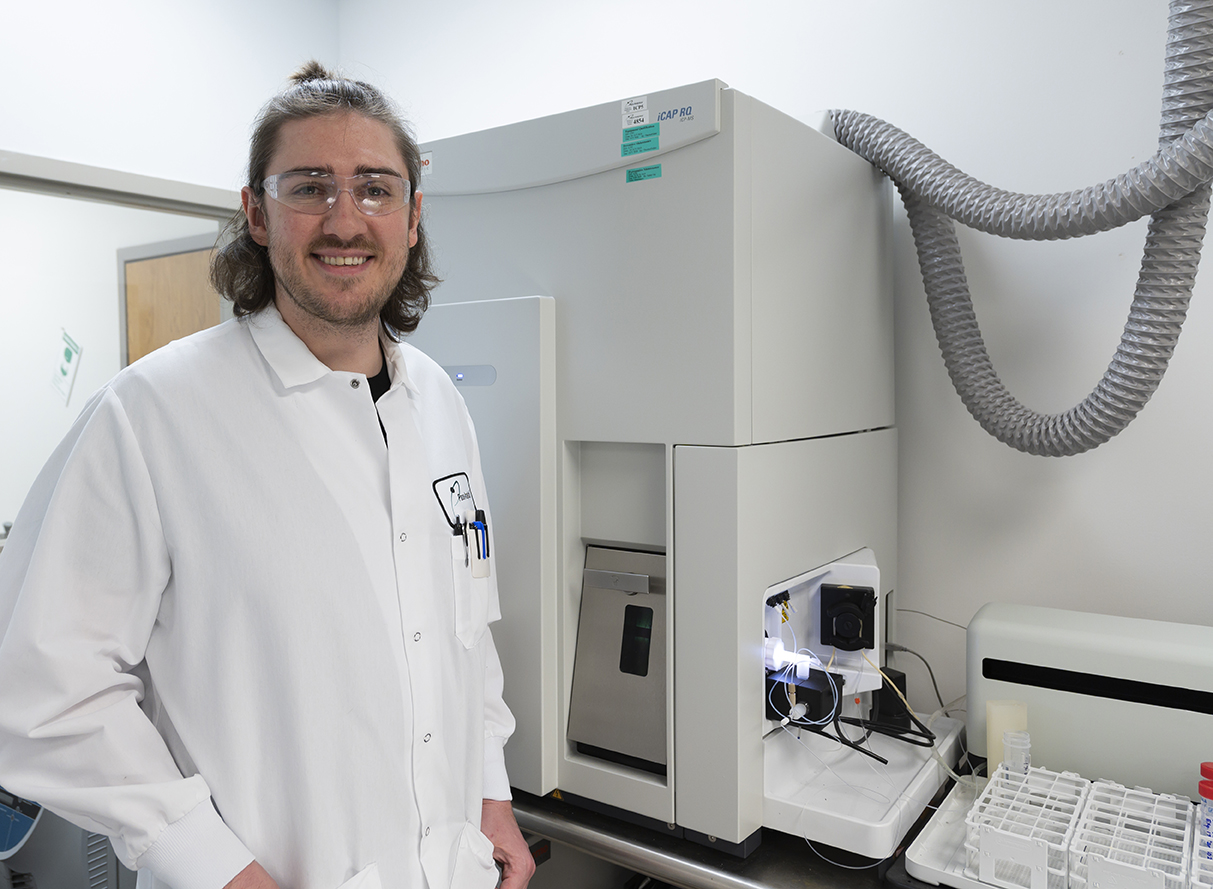

Elemental Impurities

Here we offer full-service laboratory capabilities for assessing levels of elemental impurities in raw materials, in-process formulations, finished products, and medical devices. Elemental metals may be formulated into products for functional, therapeutic, or nutritional benefits, or elementals may be natural, process, or contaminant impurities.

We provide analytical services to support compliance with Quality Control requirements whether monitoring label-claim or demonstrating control of trace-level impurities:

- United States Pharmacopoeia (USP) general chapters <232> / <233> and <661>

- European Pharmacopoeia (EP) chapters 2.4.20 and 5.20

- ICH-compliant validated methods, ICH Q3D

- Qualitative Screening methods

- Quantitative Assays

- Custom Method Development & Validation

We recently completed construction of a dedicated laboratory space for the testing of inorganic analytes including elemental metals, anions and cations. By dedicating laboratory space to this area of testing, PLS is in-step with the changing regulations and ready to help clients comply with stringent testing requirements. This space offers full-service GMP analytical laboratory capabilities with risk-reduction features, such as:

- Metal-free cabinets in sample preparation areas

- Multiple microwave digestion units with varying technology for challenging matricies

- Properly ducted hoods for acid digestions, including hazardous hydrofluoric (HF) digestions, when necessary

- A wide range of testing instrumentation

- Inductively-Coupled Plasma Mass Spectrometry (ICP-MS)

- Inductively-Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame-Aspiration Atomic Absorption Spectroscopy (AA)

- Graphite-Furnace Atomic Absorption Spectroscopy (GFAA)

- Cold-Vapor Atomic Absorption Spectroscopy (CVAA)

- Ion Chromatography (IC)

Physical Functional Testing

Patient compliance and effective drug delivery relies on the physical properties of the dosage form. From the more subtle and qualitative attributes like visual appearance and mouth feel, through the measurable performance of hardness, friability, and disintegration, on through complex requirements like adhesive characteristics of transdermals, delivered-dose uniformity of inhalation products, and the dispensing force required for pre-filled syringes (PFS), the physical characteristics of the dosage form matter.

We have more than 20 years of experience with physical testing of solid, liquid, topical, transdermal, and inhalation dosage forms, as well as devices and component systems used for drug delivery. We have a dedicated laboratory space that is both temperature- and humidity-controlled for the proper pre-test conditioning and the completion of testing.

Our Physical Testing capabilities include:

- Instron / MTS tensile testing (2-, 20-, 100-, and 200-lb load cells w/ various grips)

- Package Peel Force

- Transdermal Peel Force, peel to steel 90o and 180 o, ASTM D3330, Method A

- Release Liner Adhesion, ASTM D3330, Method D

- Probe-Tack Testing, ASTM D2979

- Shear Testing, ASTM D3654, Method A

- Viscosity Testing, rotational and capillary

- Penetrometer Testing (gels)

- Burst-Creep Package Integrity, ASTM F1140-07

- Tablet hardness / polymer hardness

- Tablet disintegration

- Syringe compression delivery force

- Needle break force

- Custom Method Development & Validation

- Custom test fixture development

The combination of a compliant GMP quality system and a broad range of physical testing capability and experience can help characterize the critical performance attributes of your delivery dosage form.

Facility Overview

Our 60,000 ft2 facility provides services to the pharmaceutical, biopharmaceutical, and medical device industries. Steady growth of our business has contributed to the recent expansion of this facility to increase our capacity and offer new capabilities. This lab serves globally with customers in North America, Europe, Asia and Africa with the ability to readily expand.

We are FDA registered, DEA registered for the handling of controlled substances, schedules I – V, and are ISO/IEC 17025 accredited. We have a long history of providing cGMP analytical laboratory services and this site has been FDA-registered for more than 30 years. We continue to invest in facilities, new technologies and state-of-the-art equipment each year.